Building Simulation

Save environment, cost, and get international recognition

BUILDING SIMULATION

Computer simulation is very useful to estimate the outcome of occupant comfort, microclimate condition, and building energy consumption, far before the building is built. Simulations are very handy to facilitate stakeholders to make informed decision on which options to take, so that the design, material choices, and equipment selections are optimized.

Building CFD Simulation Services in Australia

For achieving low energy or zero energy building, effective passive design for natural ventilation is crucial for reducing HVAC energy consumption. However, estimating air movement, air velocity, and temperature is impossible without using high performance specialist software. Likewise in designing effective active design, the resulted thermal comfort can be calculated in a more accurate manner with the use of simulation software. At Afogreen Build, we use Computational Fluid Dynamics (CFD) simulations to evaluate both passive and active elements, including underfloor cooling or heating, chilled beams, fabric ducting, ceiling fan, and ventilation systems. By accurately estimating air vector, velocity and temperature distributions, we provide insights that create comfortable and energy-efficient environments.

Understanding Building CFD Simulation

Computational Fluid Dynamics (CFD) simulation for natural ventilation uses advanced computational techniques to analyse airflow patterns within and around buildings, enabling architects and engineers to design spaces that maximise natural air movement. The significance of CFD in modern building design lies in its ability to enhance energy efficiency by reducing reliance on mechanical cooling, improve indoor air quality through effective outdoor air, and support sustainable design goals by providing data for green building compliance.

Benefits of Building CFD Simulation

CFD provides critical insights that allow architects and engineers to optimise designs for maximum occupant comfort and functionality. It identifies potential areas of stagnant air, enabling improvements in ventilation strategies and reducing reliance on mechanical systems, which ultimately leads to greater energy efficiency.

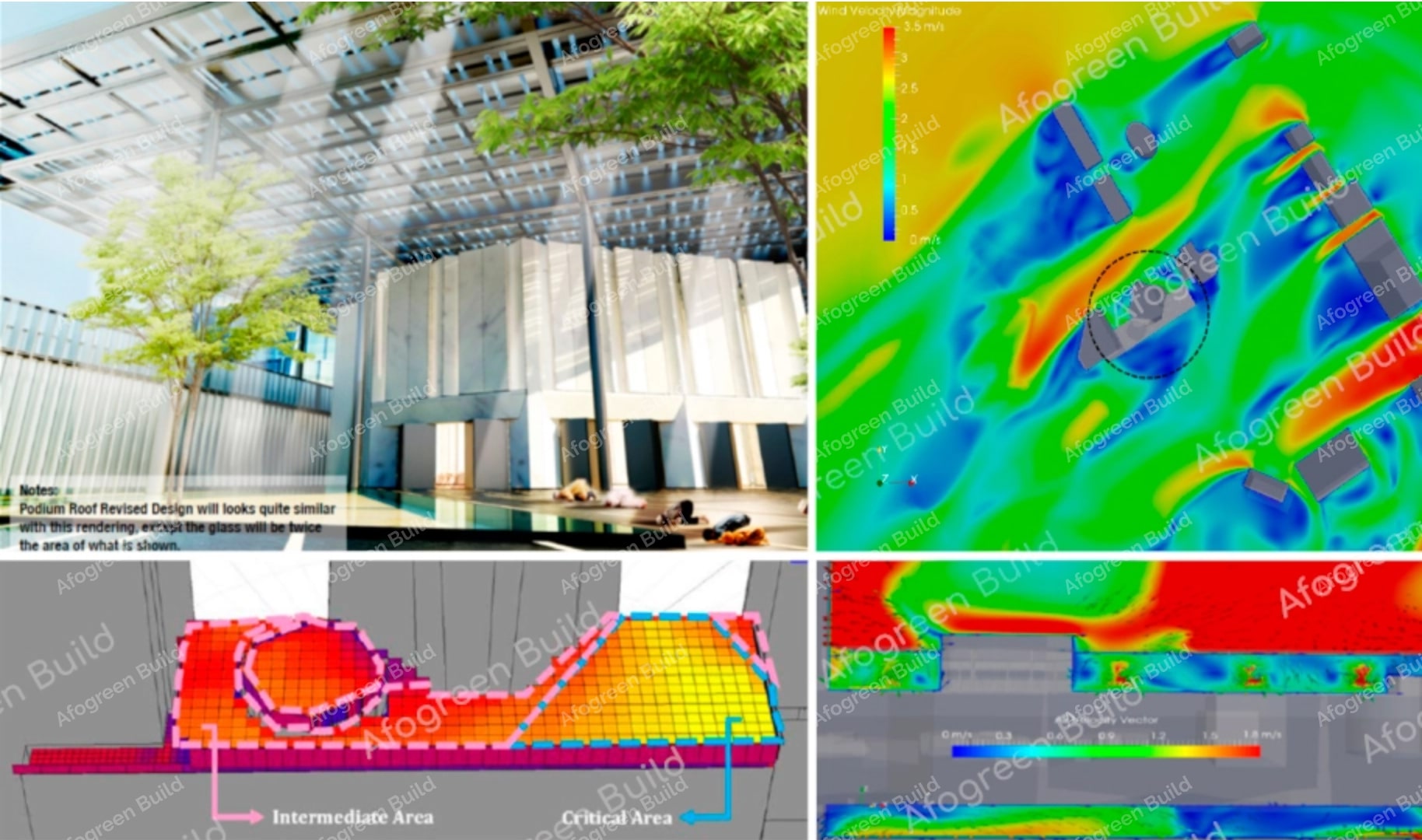

Case study 1:

We did multistorey bus depot featuring four sides of parapet walls and weather screens. These elements are integral to the design and function of the depot. The architect’s goal is to achieve thermal comfort for the occupants through passive design as much as possible to make the building Super Low Energy.

However, the challenge is that the building is very wide, and relying solely on the openings above the parapet walls on the four sides of the building is impossible. Consequently, air wells were added to enhance the air velocity in the building.

In this project, the CFD simulation allowed the architect to evaluate the sufficiency of the air wells and determine optimal opening sizes. The analysis provided insights into air velocity and temperature distributions, helping the design meet thermal comfort goals.

Case study 2:

In our CFD simulation project for nursing homes, we aimed to meet an average air velocity of no less than 0.6m/s to maintain comfort for the residents. Several strategies were implemented to achieve this, including adding operable windows for controlled natural ventilation, increasing the openings of interior walls and grills to enhance airflow, and shifting window placements to optimize airflow paths. Additionally, wind scoops were integrated into the building’s exterior to direct wind into the space, while ceiling fans were installed in areas with insufficient natural ventilation. These measures collectively helped the required air velocity, creating a comfortable and energy-efficient environment for the nursing home residents.

Case study 3:

We were tasked to study air velocity in and around a complex of high-rise mix development near the sea. The air velocity from the sea is very high. The design team was concerned about whether a windbreaker may be needed to reduce air velocity before reaching the mixed development, as the strong wind may cause safety issues aside from comfort issues. In this case, we helped the design team determine which air velocity profile to study and simulated the air vectors in and around the high-rise mix development. The design team then used the simulation result to consider the need to add a windbreaker and the location, shape, and size of the windbreaker.

The CFD Simulation Process

1. Define objectives

We begin by identifying your specific goals for the simulation. This helps tailor our approach to meet project needs.

2. Create the surrounding building, simplify the 3D model, and propose wind direction

We create the surrounding building and simplify the 3D modelling provided by the client, incorporating all relevant features. This step also includes determining the proposed wind direction. We then mesh the model into smaller elements to capture airflow patterns accurately.

3. Run the simulation, analyse results, and prepare a report

We execute the CFD simulation, calculating wind speed and temperature distributions based on actual conditions and analyse the results, including the air vector, to assess ventilation effectiveness and prepare a comprehensive report.

4. Optimise design

If necessary, we will recommend design adjustments to enhance natural ventilation, guiding the project toward meeting performance goals.

Technologies and Tools

We use advanced tools system to run the CFD simulation. The software offers several advantages that contribute to providing accurate and reliable results in Computational Fluid Dynamics (CFD):

1. Extensive Range of Applications: The software includes solvers tailored for different physical problems, from incompressible steady state to complex multiphase flows. This specialisation allows users to select the most appropriate simulation tools, enhancing accuracy.

2. Robust Numerical Methods: The software employs advanced numerical techniques for solving partial differential equations, contributing to the simulation’s accuracy. Users can select solvers based on their numerical requirements, supporting optimal performance for their case.

3. Parallel Processing: The software supports automatic parallelisation, allowing users to run simulations on multiple processors. This capability speeds up computations and enables handling more significant, complex models, leading to more reliable results.

Applications Across Industries

Applications Across Industries: Versatility of CFD Simulation

1. Residential Buildings

In residential design, CFD simulations help optimise natural ventilation to improve indoor air quality and occupant comfort. By analysing airflow patterns, designers can strategically place windows and vents to help effective cross-ventilation, reducing reliance on mechanical cooling systems.

2. Commercial Buildings

CFD is instrumental in creating comfortable work environments and energy efficiency in commercial developments. In office buildings, CFD simulations can evaluate the effects of layout changes on airflow, possible backflow from kitchen exhaust into outdoor air intake, possible short circuits from one cooling tower to another, etc.

3. Industrial Facilities

Industrial facilities often have specific indoor air performance requirements, depending on the type of industry. CFD simulations are crucial for evaluating whether the HVAC design can meet indoor air performance requirements. After achieving compliance with indoor air performance, CFD simulation can support the feasibility study of optimization of the HVAC design by simulating various scenarios using different inputs. The project team can compare the results of these various scenarios in terms of energy reduction without neglecting compliance with the owner’s project requirements. CFD simulation is also helpful in tracking the possible smell or pollutant flow in the air. Based on CFD simulation results, the designer can prevent the flow of smell or pollutants into sensitive areas through careful layout planning, exhaust fan provision, etc.

4. Data Centres

Hot spots shall be prevented in any data hall in data centre buildings. CFD simulations are important to enable the designer to identify any hot spot and take the required corrective action. CFD simulation is also useful for further optimization, such as checking the possibility of increasing the air supply temperature in combination with the use of hot or cold aisles in a data hall. By doing so, CRAH energy can be saved.

5. Sports Halls, Auditoriums, and Other High-Volume Buildings

Sports halls, auditoriums, and other types of spaces requiring high ceilings likely use unconventional air conditioning systems, such as fabric ducting, underfloor cooling or heating, chilled beams, etc. As the systems used are unconventional, further checks are needed to tailor the size, discharge opening, air velocity, air supply temperature, etc. CFD simulation is beneficial to check these. If CFD simulation results show any undesired conditions, the designer can adjust the design and setting parameters until the CFD simulation results show the desired conditions.

Why Choose Afogreen Build

Afogreen Build stands out in the industry with over 20 years of extensive expertise and experience. We understand that each project has its characteristics and challenges, and our highly skilled team focuses on collaborating closely with clients to deliver customised solutions.

We also prioritise sustainability by enhancing energy efficiency while offering detailed reports that provide actionable insights and recommendations for informed decision-making.

Let’s discuss your project in detail so we can provide you with the most effective solutions. Reach out today, and together we’ll elevate your building design to new heights!

Frequently Asked Questions (FAQ)

How long does the CFD simulation process take?

The duration of the CFD simulation process varies depending on the project’s complexity and specific goals. Generally, the entire process can take several weeks, from defining objectives to analysing results. For further information, please get in touch with us (link to the enquiry form).

How much does CFD simulation cost?

The cost of CFD simulation varies based on project complexity, building size, and specific analysis requirements. We offer competitive pricing and will provide a detailed quote after understanding your project needs. Please contact us for further information (please link to the from).

What data do I need to provide for a CFD simulation?

To conduct an effective CFD simulation, you must provide information such as building geometry, boundary conditions (like outdoor wind speed and direction), and any specific ventilation strategies you want to explore.

How can I get started with CFD simulation for my project?

To get started, contact us at Afogreen Build for a consultation. We’ll discuss your project requirements and challenges, assess your needs, and outline how our CFD simulation services can provide tailored solutions to enhance your building design.

How do I ensure my project data is secure during the CFD simulation?

At Afogreen Build, we prioritise data security and confidentiality. We implement strict protocols to protect your project information throughout the CFD simulation process, ensuring your data remains secure.